Five hundred people lose limbs in the United States every day, yet there is no government agency to protect amputees’ interests, according to the Centers for Disease Control and Prevention.

Earlier this year, Glori Das, biomedical engineering and neuroscience freshman, founded a UT chapter of a global organization, e-NABLE, that works to address this very issue. Its members provide 3-D printed hands, fingers and forearms to amputees free of cost. Das said she wanted to start a chapter at UT as soon as she first heard about the organization.

Das started the chapter with other founders, including biochemistry freshman Arjun Menta.

“My drive to help others and improve their lives for the better was my motivation for helping found this club,” Menta said.

Anyone looking for a new hand can submit a request online with e-NABLE or register through a separate prosthetic support organization. They are then matched with nearby volunteers from e-NABLE who guide them through the process.

“We work with amputees as well as their orthopedists to ensure the prosthetics fit properly,” Das said.

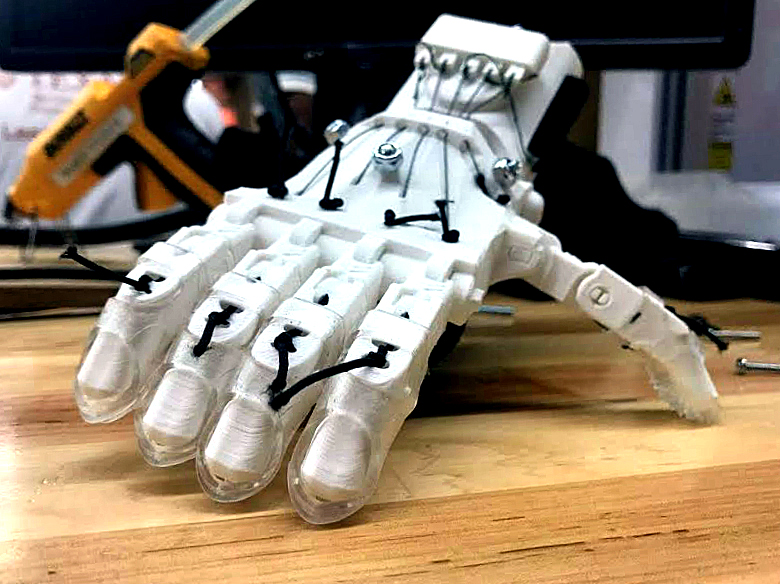

Members can choose from an open database of pre-designed hands to print or can design their own using programs like MakerBot Desktop. The UT chapter uses the Engineering Makerspace in the mechanical engineering building to print their hands.

The hands are made out of a biodegradable polymer called PLA, or polylactic acid, and filaments of a more versatile material called ABS, or acrylonitrile butadiene styrene. After the hands are printed, other fixtures such as screws, elastics and fishing lines can be used to connect the individual pieces.

“Medical-grade prosthetics (can) cost tens of thousands of dollars,” Das said. “The hands we print are around $40…so organizations like e-NABLE are important.”

In addition, e-NABLE works to fill a gap in access to prosthetics. According to Das, insurance companies see frequent prosthetic replacements as a liability, which is often the case for growing children. E-NABLE has specialized models for these children and can provide hands for children as young as four years old.

The hands are usually mechanical attachments; however, a forearm model has been developed that is myoelectric, or powered by electrical impulses from the muscles. This model uses a muscle sensor connected to the body by skin electrodes, according to Das and Menta.

Biomedical engineering freshman Shan Ali said while the hands can be used in most situations, it’s recommended to wear a glove while eating and take it off while showering because certain liquids, such as bleach, can damage the hands.

E-NABLE has already been invited to host two hand-a-thons, or day-long events where they will teach people to assemble printed 3-D parts. Das said e-NABLE hopes to help make over 80 hands at these events. The organization has also volunteered at local schools to help design prosthetics with specific tasks, such as baking or applying

nail polish.

In the upcoming year, e-NABLE will be working on making wrists that can rotate 360 degrees, 3-D-printed toes and assistive hands devices for the blind as well as improving the myoelectric device.

“The ability to help others directly and make a difference in their lives is an amazing experience that I would urge everyone to seek out,” Menta said. “(The) effect that a limb can have on another person is very profound.”

E-NABLE is open to all majors and can teach new members 3-D printing skills and techniques.