UT students are using oil from University buildings to create their own biodiesel fuel that will eventually be used in University vehicles.

In 2013, a group of students from Engineers for a Sustainable World were awarded $15,000 by the Green Fee Committee — a University funded grant for projects

related to sustainability — to purchase a biodiesel reactor. UT graduate Kendall Ernst, author of the proposal and former project head, said the group will use the reactor to convert leftover grease from University dining halls and buildings into biodiesel for UT transportation vehicles.

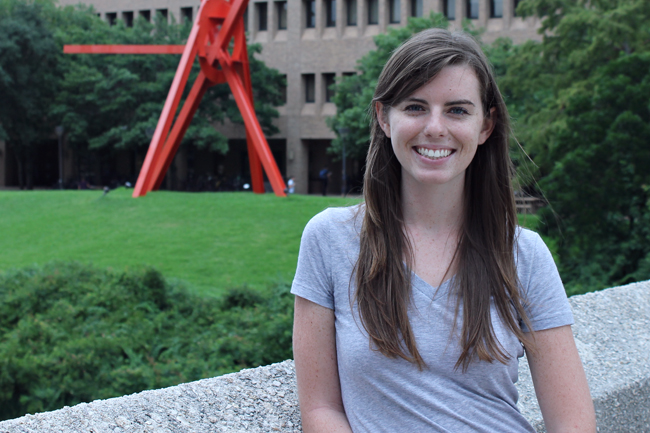

Claire Sembera, current project head and civil engineering senior, was awarded $7,400 for continued production costs. She said the reactor is currently being assembled and stored at the Pickle Research Campus and she hopes to begin releasing test batches of the fuel by the end of October.

“We [will make] small 40-gallon batches, the size of our reactor, and producing those maybe once a month to try and get our quality right, then hopefully by fall 2015 we can start inputting it into vehicles,” Sembera said.

Sembera said the new funding will be used to buy chemicals and conduct maintenance on the reactor. She said the team will also hire a lab manager and an Austin biofuel expert to instruct the team and students in a seminar series

According to Ernst, the team spent last year getting approval from the University to buy a reactor, find a safe place to store it and find a fuel supply.

“Once we solved all of those hurdles, we actually had to order the reactor, and that took a lot longer than expected,” Ernst said.Ernst said biodiesel is a fuel created from biological materials that produce oil instead of fossil fuels or coal. He said using grease is sustainable because it is recycling waste.

“Instead of using a bunch of water and fertilizer to grow crops, we’re using a waste product that would normally be thrown away or turned into something else,” Ernst said. “Using that waste product, you create a fuel so you have a lesser overall environmental impact.”

UT Parking and Transportation Services currently offers biodiesel as a fueling option. Fleet manager Mark Kaligian, who has been working with the students, said that out of about 600 PTS vehicles, 50 take diesel and biodiesel fuel. According to Kaligian, PTS’ biodiesel is bought from a state fuel contract.

“We use it seasonally. It tends to gel at very cold temperatures, and that will clog fuel filters,” Kaligian said. “So, typically we’ll use biodiesel from about mid-March to mid-September, when there’s warmer temperatures.”

Ernst said the actual process of creating the biodiesel is straightforward.

“Take the oil, you put it into a vat, then you add catalysts, which is a base like sodium hydroxide. Then you add methanol, which is an alcohol, and it undergoes this reaction called ‘transesterification,’” Ernst said. “Basically, the triglycerides in the oil get turned into fatty acid methyl esters, which are chemically equivalent to diesel fuel.”

Sembera said she thinks the recycling of waste to create biodiesel will provide another dimension to UT’s sustainability efforts.

“This is important because it’s taking that next step of reducing the fuel imprint, along with emissions and fuel intake at the University, making it a more sustainable campus,” Sembera said.