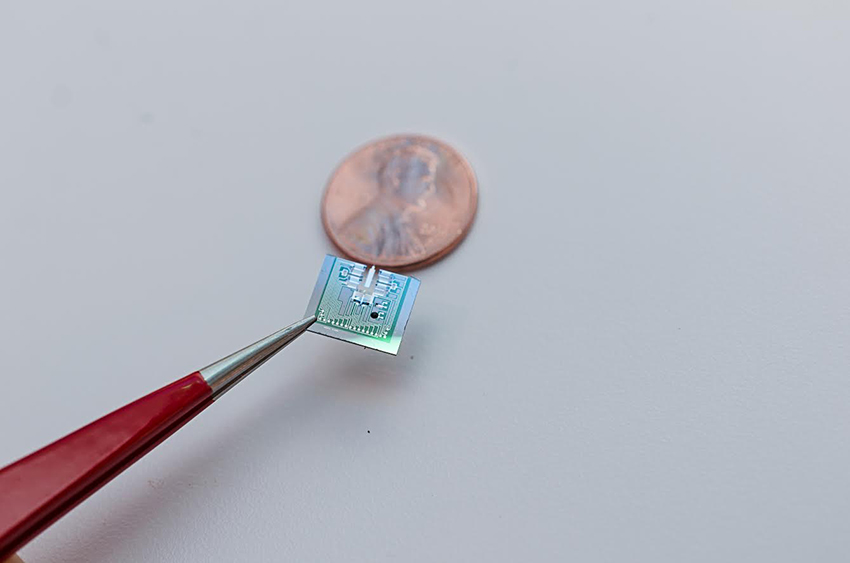

The new molecular-level microscope built by UT-Dallas researchers is smaller than size of a dime.

Reza Moheimani, a professor of mechanical engineering, who heads the UT-Dallas Laboratory for Dynamics and Control of Nanosystems, recently worked to reduce the size of atomic force microscopes (AFMs), which are capable of visualizing individual atoms. He and his team succeeded in scaling down AFMs from roughly the size of an office desk to just one square centimeter. They published their work earlier this month.

“For the past several years, a group of my students and postdocs and I have been working systematically to design a device that has all the functionalities of the AFM, but fits on a single silicon chip,” Moheimani said.

Anthony Fowler, a research scientist in the lab, said that AFMs allow scientists to collect data on materials all the way down to the nanometer level.

The team built the microscope based on microelectromechanical systems, or MEMS, technology, which enables smartphones to measure user’s movement and orientation in space. MEMS allowed them to significantly reduce the size of the microscope, Fowler said.

Fowler said standard AFMs each have a probe on their tips. This probe has different modes that allow it to glide across the surface of materials and measure the force between the probe and the material, yielding distinct 3D information on the properties of the materials, he said.

In one of the modes of AFMs, called the tapping-mode, the microscope’s probe moves along the sample material, rapidly moving and coming into and out of contact with the material, according to Moheimani. He added that tapping mode is helpful when analyzing live samples, which can be quite delicate and become damaged during other modes which sustain continual contact with the sample.

The probe adjusts its movement using built-in feedback loops, said Mohammad Maroufi, a research associate in mechanical engineering and Moheimani’s partner throughout the discovery.

“The feedback controller then adjusts the actuation signal going into the device based on the sensors’ output,” he said.

In addition to reducing the size, the team also hopes to significantly reduce the price of AFMs, Moheimani said. Standard AFMs can cost upwards of over a half-million dollars, but the new invention would be a fraction of this price, he added.

“I would expect a commercial version of this system would not be over a few thousand dollars,” Moheimani said.

Moheimani said current AFMs are rarely able to provide images of fast time-lapsed processes, such as those of living samples. He added that the team hopes to further refine their prototype device to be capable of measuring time-lapsed image.

“The ultimate goal is to evolve this technology to achieve video-rate AFM capability on a single chip,” Moheimani said.